Wp-31 semi automatic ultrasonic hose filling and sealing machine

Equipment introduction:

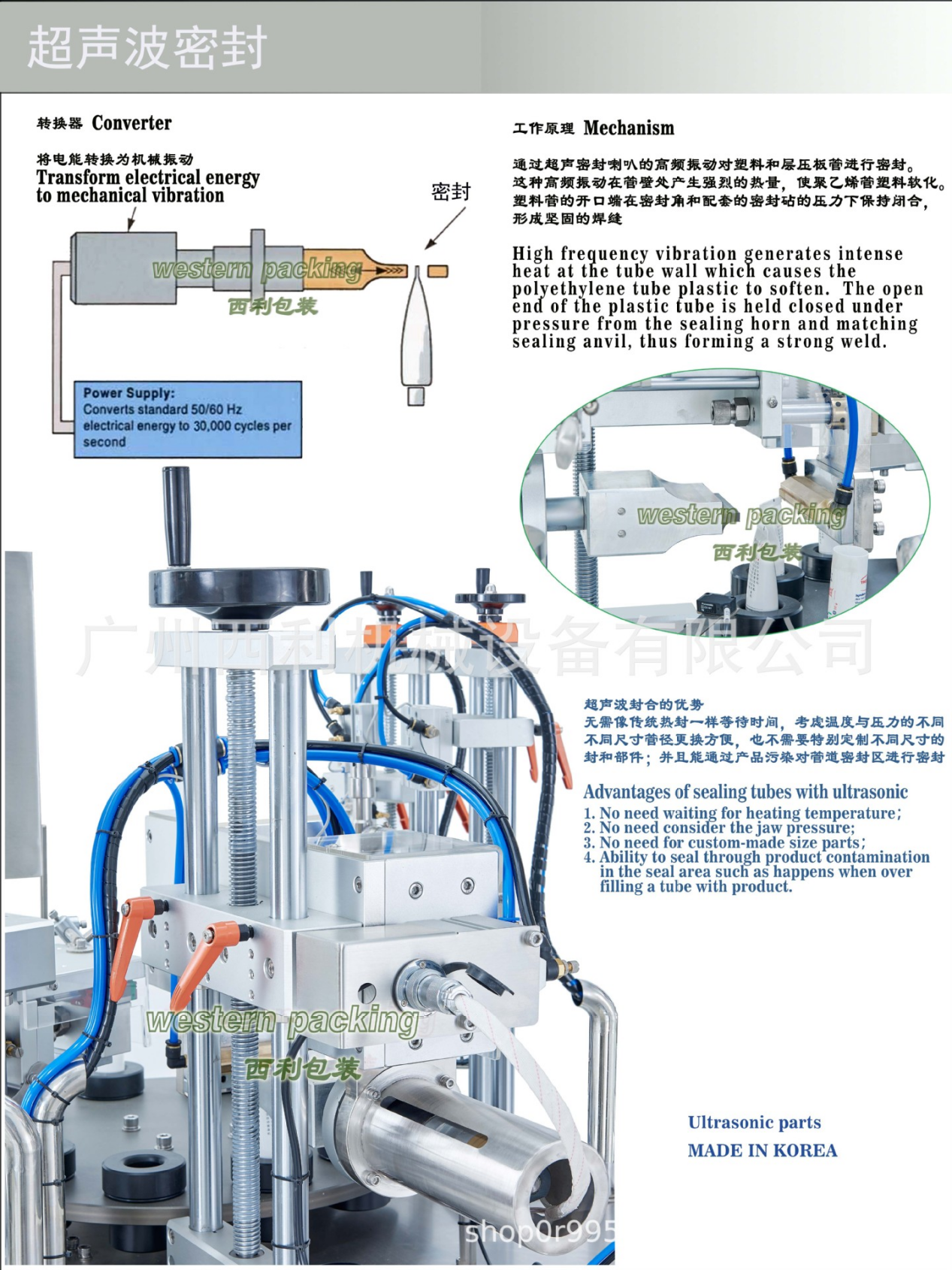

Ultrasonic sealing machine is an advanced equipment for sealing plastic hose. It uses ultrasonic wave to make the sealing part of plastic hose produce high impact heat by the action of transducer and melt to bonding quickly. Therefore, it does not need any auxiliary products. It has the advantages of fast sealing speed, good quality and beautiful appearance. It has little influence on chemical agents and is not afraid of surface pollution. It also solves the shortcomings of using adhesive or hot fusion welding. It breaks the traditional heating mode.

Machine advantages:

1. The machine adopts ultrasonic technology to seal, and the sealing effect is stable and durable; the seal lines are clear and not deformed;

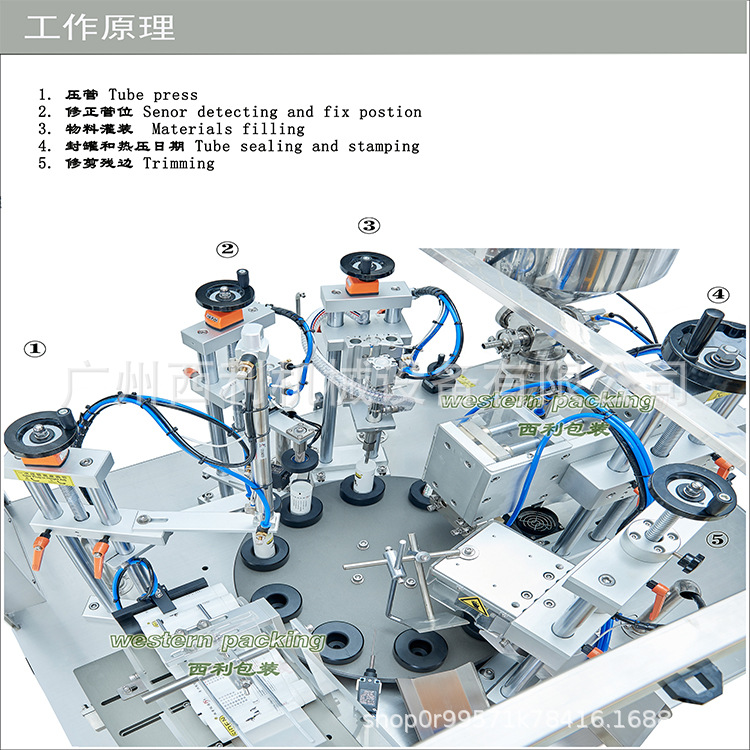

2. Manual pipe dropping, press the start button, the machine automatically benchmarking, filling, sealing, coding and tail cutting, easy and fast operation;

3. Independent research and development of digital ultrasonic automatic frequency tracking electric box, no need to manually adjust the frequency, increase the power automatic compensation function, will not reduce the machine power due to long service time, can freely adjust the power according to the hose material and size, stable output, low failure rate, and longer service life than ordinary electric box;

4. PLC touch screen is used for control, which is easy to operate;

5. The whole machine is made of 304 stainless steel, which is resistant to acid, alkali and corrosion;

6. The Japanese Panasonic high sensitive benchmarking electric eye is equipped with stepping motor, which makes the benchmarking speed fast and accurate;

7. The filling accuracy can be controlled within ± 1% by using paste liquid dual-purpose filling machine;

Performance and features: 1. The machine adopts manual pipe dropping, automatic benchmarking, filling, sealing, coding, tailing and finished product output, easy and convenient operation;

2. Accurate positioning of ten position divider to reduce the defective rate;

3. Using ultrasonic technology to seal, the sealing effect is stable and lasting, and the sealing lines are clear without deformation;

4. The whole machine is made of 304 stainless steel, which is resistant to corrosion, acid and alkali;

5. The machine is equipped with automatic identification system, no tube, no filling and no sealing, so as to reduce the loss rate of machine and mould;

6. Use anti dripping filling head;

7. PLC touch screen control is adopted, and the fault alarm system is configured. The fault information is displayed on the touch screen, which is clear at a glance and can quickly locate and solve problems;

8. The company is equipped with mold frequency tester to match the mold frequency with the machine to extend the service life of mold and electric box;

9. Independent research and development of digital ultrasonic automatic frequency tracking electric box, no need to manually adjust the frequency, increase the power automatic compensation function, will not lead to the decline of machine power because of long service time, can freely adjust the power according to the hose material and size, stable output, low failure rate, longer service life than ordinary electric box.