WP-Y31 Automatic Ultrasonic Tube Filling and Sealing Machine

Equipment introduction:

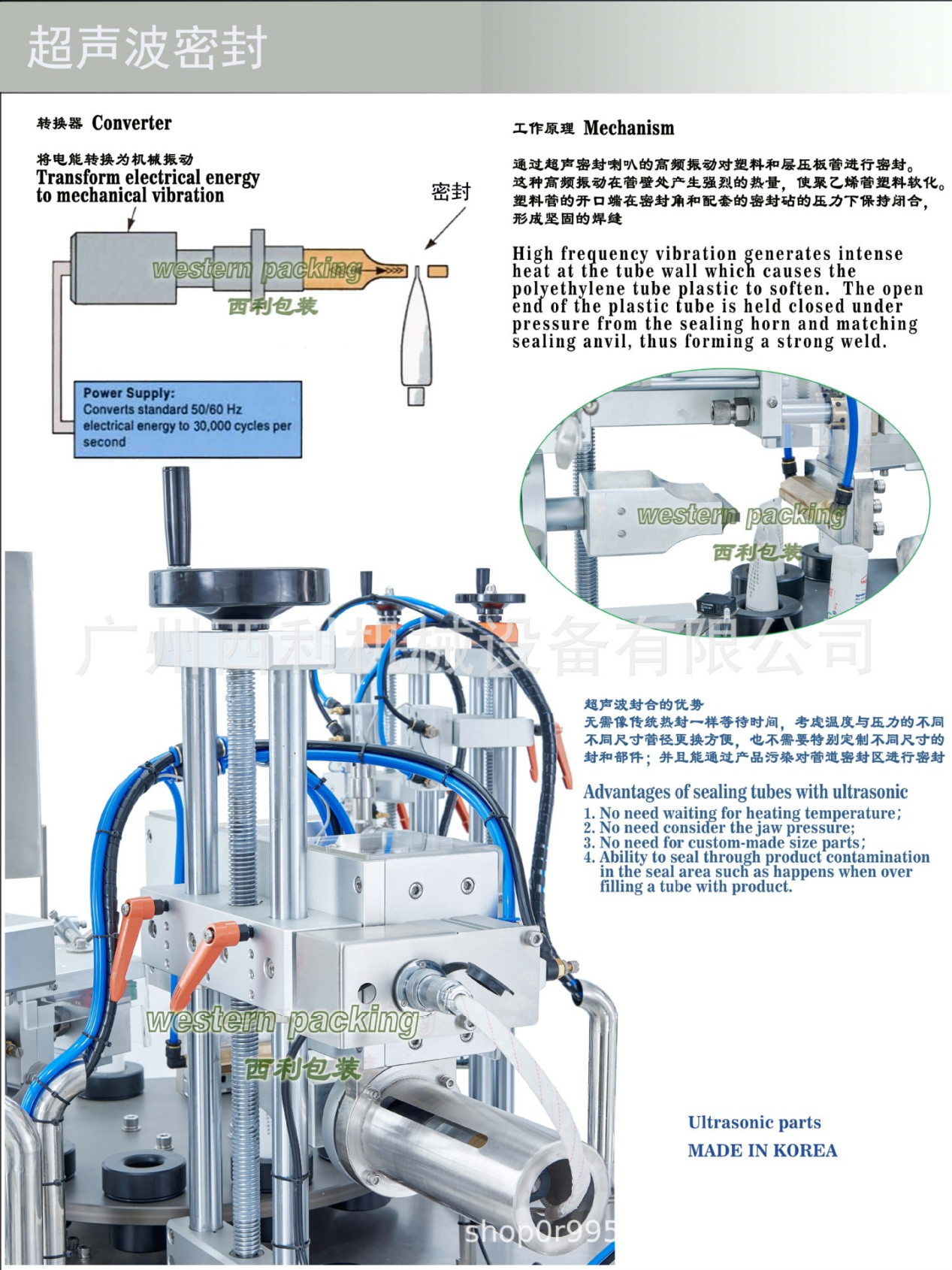

Ultrasonic sealing machine is advanced equipment for plastic hose sealing. It uses ultrasonic waves to make the plastic hose seal produce high heat and quickly melt to bond through the action of the transducer. Therefore, it does not need to add any auxiliary products. The sealing speed is fast, the quality is good, the appearance is beautiful, and the advantages are little impact on chemical agents. The pollution is still sealed, which solves the shortcomings of using adhesives or hot melt welding. Break the traditional heating method.

Machine advantages:

1. The machine adopts ultrasonic technology to seal, and the sealing effect is stable and lasting; the lines at the sealing are clear and not deformed;

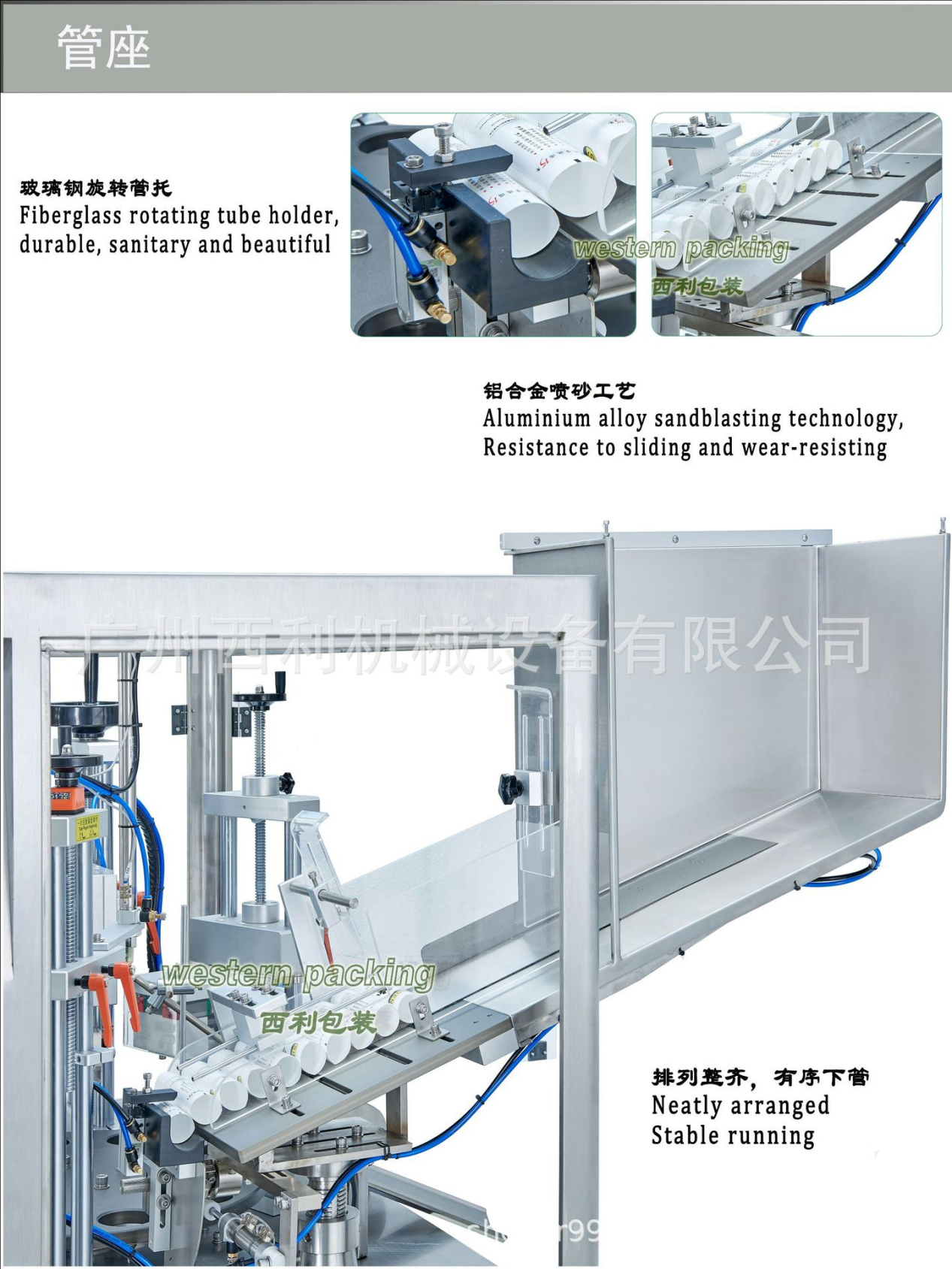

2. Automatically drop the tube, the machine will automatically mark, fill, seal, code and cut the tail, the operation is convenient and quick;

3. Independent research and development of digital ultrasonic automatic frequency tracking electric box, no need to manually adjust the frequency, increase the power automatic compensation function, will not reduce the power of the machine due to long use time, can adjust the power freely according to the hose material and size, the output is stable, and the failure Very low rate, longer service life than ordinary electric boxes;

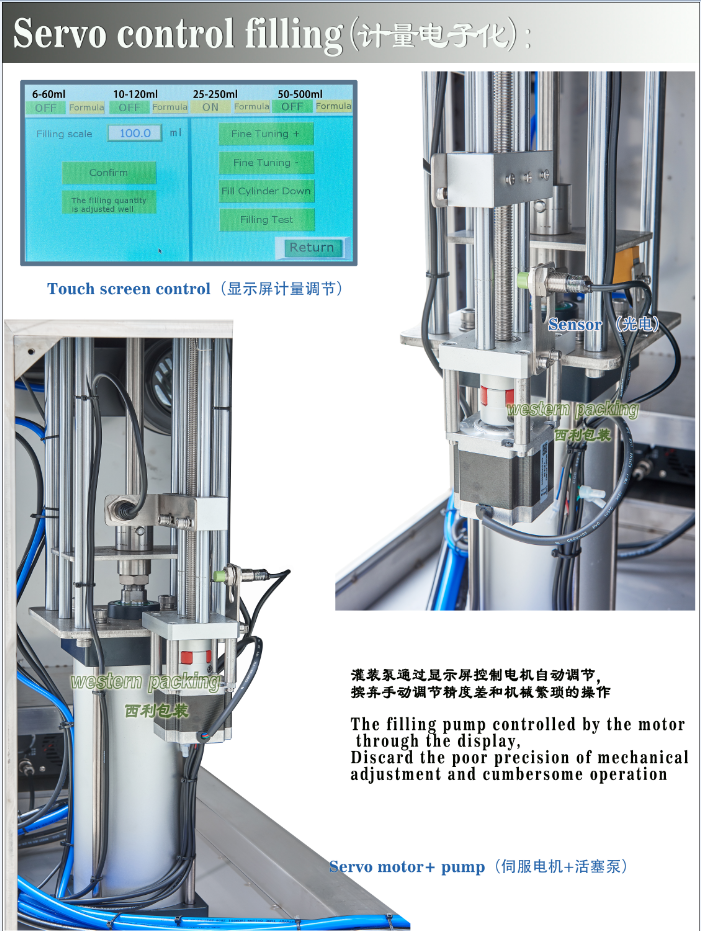

4. Controlled by PLC touch screen, easy to operate;

5. The whole machine is made of 304 stainless steel, which is resistant to acid and alkali and corrosion;

6. Adopting Japanese Panasonic high-sensitivity standard electric eye configuration stepping motor, the standard speed is fast and accurate;

7. Adopting dual-purpose filling machine for paste and liquid, the filling accuracy can be controlled within ±1%;

Performance and characteristics:

1. This machine adopts automatic drop tube, automatic machine labeling, filling, sealing, coding, tail cutting and finished product output, easy and convenient operation;

2. The ten-station divider is accurately positioned to reduce the rate of defective products;

3.Using ultrasonic technology to seal, the sealing effect is stable and lasting, the sealing pattern is clear and does not deform;

4. The whole machine is made of 304 stainless steel, which is resistant to corrosion, acid and alkali;

5. This machine is equipped with automatic identification system, no tube, no filling and no sealing, reducing the loss rate of the machine and mold;

6. Adopt anti-drip filling head;

7. Use PLC touch screen control, configure fault alarm system, fault information is displayed on the touch screen, clear at a glance, can quickly locate and solve the problem;

8. The company configures the mold frequency tester to compare the mold frequency with the machine

Large-scale matching to extend the service life of molds and electric boxes;

9. Independent research and development of digital ultrasonic automatic frequency tracking electric box, no need to manually adjust the frequency, increase the power automatic compensation function, will not reduce the power of the machine due to long use time, can freely adjust the power according to the hose material and size, the output is stable, and the failure The rate is extremely low, and the service life is longer than ordinary electric boxes.